Print Methods Glossary

Custom Folders can be created using a variety of different print

methods. Below are detailed descriptions of each print method to help

you make a decision on what works best for your specific project.

Whether you're looking for Foil-Stamped Folders, Printed Folders,

Embossed Folders, or any combination of those options, we'll help you

create the perfect custom Folder!

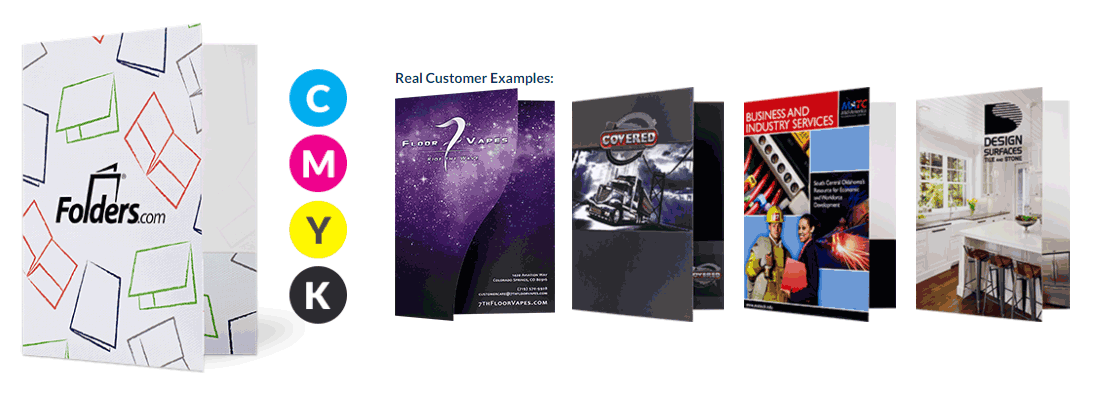

Full-Color Printing

Full-color printing is a great folder decorating method for reproducing images and artwork. If your design includes full-color photographs, four-color printing is required. The Full-color printing process is also known

as CMYK or Four Color Printing. CMYK stands for cyan, magenta, yellow, and key (black). This is the industry standard in producing full color printed media that we apply to custom folders.

Please be aware that with four-color printing a very subtle shift in color may occur from the original design due to the folder color you choose, and several other factors.

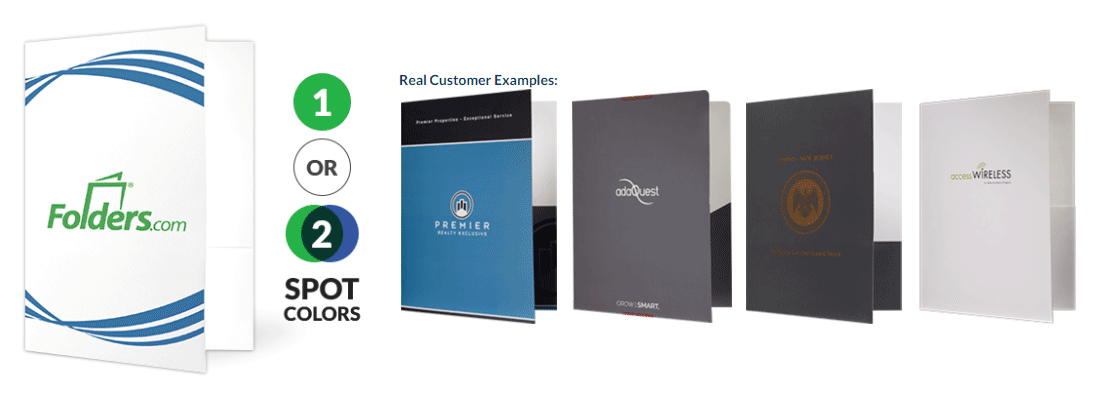

Spot Color

Spot color refers to color produced in offset printing by a single ink. A spot color could be a "pure" color, or a color that's pre-mixed to a set formula. For designs that need an exact color printed, a spot color is used because it's the most efficient method of controlling color. In brand marketing, across graphic elements such as text, icons and backgrounds, spot color offers consistent color matching.

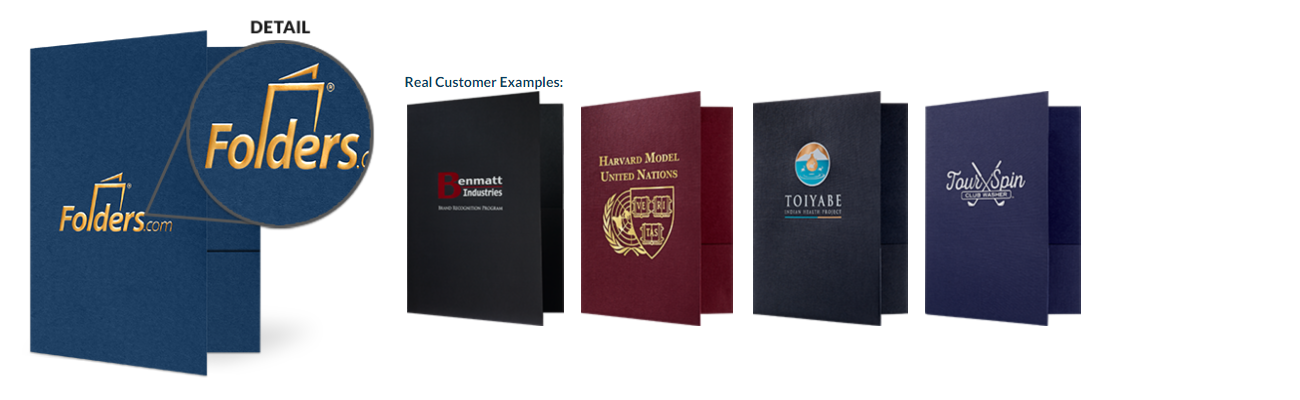

Foil Stamping

Foil stamping is one of the methods we use to apply artwork to our paper folders and padded certificate holder products. It's the best method available for decorating colored paper. Artwork for foil stamping should

be "line art" using only solid fills and lines without half-tones or screen tints. The artwork is applied to the paper using heat and pressure, and will generally leave a slight flat indentation of the foil into the paper.

Our most popular foil colors are displayed in our Foil Color Chart. Metallic foils include gold, silver, and a range of metallic colors with mirror or matte finishes. Non-metallic foil colors have a gloss finish. Other types of foils are available on a special-order basis including holographic patterns, matte finish non-metallic colors, pastel colors, pearlescent colors, and tint foils.

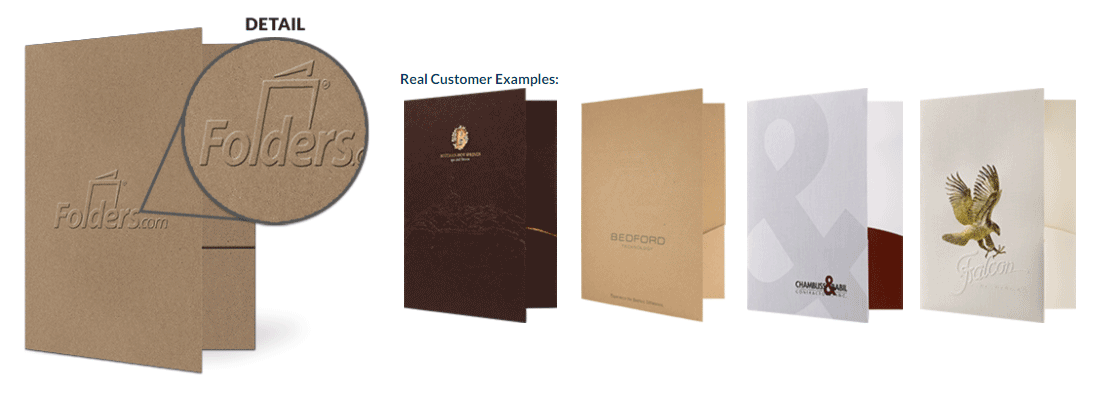

Embossing

Most types of paper can be embossed, and size is not normally a consideration. Embossing without ink, so that the image is raised but not colored, is called "blind embossing." Embossing used in conjunction with ink,

so that the raised area is colored, is called "color register embossing." "Debossing" is similar to embossing, but recesses the design rather than raising it. Embossing used in conjunction with foil stamping is called

"combination stamping" or "combo stamping." Embossing is typically accomplished by applying heat and pressure with metal dies, usually made of copper or brass, that fit together and squeeze the fibers of the

substrate. The combination of pressure and heat raises the level of the image higher than the substrate.

Understanding Different Printing Techniques

This article will serve as a comprehensive guide to different printing techniques, providing readers with a glossary of print methods and their applications. Readers will learn about offset printing, digital printing, screen printing, flexography, and gravure printing. Real-world use cases and examples will be provided to showcase the effectiveness of each printing method in various industries.

Offset Printing

Offset printing is a commonly used printing technique that involves transferring an inked image from a plate to a rubber blanket, then onto the printing surface. This process is ideal for high-volume printing jobs due to its efficiency and cost-effectiveness. However, offset printing requires more setup time and is not suitable for short print runs.

Advantages of Offset Printing

One of the main advantages of offset printing is the high image quality it produces. The colors are vibrant and consistent, making it ideal for projects that require precise color matching. Additionally, offset printing can handle a wide range of paper types and sizes, giving businesses flexibility in their printing options.

Disadvantages of Offset Printing

Despite its many benefits, offset printing has some drawbacks. It is not cost-effective for small print runs, as the setup costs can be high. Additionally, offset printing requires more time for setup and production compared to digital printing, making it less suitable for projects with tight deadlines.

Common Uses of Offset Printing

Offset printing is commonly used for producing items such as brochures, magazines, catalogs, and stationery. Its ability to produce high-quality images and text makes it a popular choice for businesses looking to create professional marketing materials.

Digital Printing

Digital printing is a modern printing method that involves transferring digital files directly to the printing surface. This process eliminates the need for plates, making it ideal for short print runs and projects with quick turnaround times. Digital printing is known for its high-quality results and cost-effectiveness for small quantities.

Advantages of Digital Printing

One of the main advantages of digital printing is its ability to produce high-quality prints quickly and cost-effectively. Digital printing does not require plates, reducing setup time and costs. Additionally, digital printing allows for variable data printing, making it ideal for personalized marketing materials.

Disadvantages of Digital Printing

While digital printing is great for short print runs, it may not be as cost-effective as offset printing for large quantities. Digital printing also has limitations in color accuracy and paper options compared to offset printing. Additionally, digital prints may not be as durable as offset prints, especially for items that require frequent handling.

Who Can Benefit from Offset Printing?

Offset printing is ideal for businesses and individuals who require high-quality printed materials in large quantities. Here are some specific groups that can benefit from offset printing:

- Marketing agencies looking to produce brochures, flyers, and posters for their clients.

- Publishers needing to print magazines, catalogs, and books in bulk.

- Businesses looking to create professional stationery, business cards, and envelopes.

When to Utilize Digital Printing?

Digital printing is a versatile printing method that can be used in various situations. Here are some scenarios where digital printing is the best choice:

- When you need to print a small quantity of materials quickly.

- For projects that require variable data printing, such as personalized direct mail campaigns.

- When you want to test different designs or versions of a printed piece before committing to a large print run.

Examples of Successful Screen Printing Projects

Screen printing is a versatile printing technique that can be used in a wide range of industries. Here are some examples of successful screen printing projects:

Apparel Industry

- Custom t-shirts for events, sports teams, and promotional giveaways.

- Branded uniforms for businesses, schools, and organizations.

Signage and Display Industry

- Banners and flags for outdoor advertising and events.

- Posters and signs for retail stores, restaurants, and trade shows.

Industrial Applications

- Printed circuit boards for electronics manufacturing.

- Labels and packaging for consumer products.

What Sets Our Product Apart

Our product stands out from the competition due to its innovative features and high-quality results. We use cutting-edge technology to ensure that every print is crisp, vibrant, and professional. Additionally, our product offers a wide range of customization options, allowing users to create unique and personalized printed materials.

Customization Options

One of the key features that make our product special is the ability to customize every aspect of the print. From colors and fonts to paper types and finishes, users have full control over the final product. This level of customization ensures that each print is tailored to the specific needs and preferences of the user.

Applications of Our Product

Our product is versatile and can be used in a variety of industries and settings. Here are some common use cases for our product:

- Marketing materials such as brochures, flyers, and posters.

- Business cards, stationery, and promotional items.

- Event signage, banners, and displays.

Custom Marketing Campaigns

One of the unique applications of our product is the ability to create custom marketing campaigns. By leveraging our customization options, businesses can design targeted marketing materials that resonate with their audience. This personalized approach can lead to higher engagement and conversion rates for marketing campaigns.

Tips for Maximizing Your Experience

To get the most out of your adventure with our product, follow these tips:

- Take advantage of our customization options to create unique and eye-catching prints.

- Work closely with our design team to ensure that your vision is brought to life in the final product.

- Experiment with different paper types and finishes to find the perfect combination for your project.

Collaborate with Our Experts

For complex projects or large print runs, consider collaborating with our team of experts. Our experienced designers and printers can provide valuable insights and recommendations to help you achieve the best results with our product.

Practical Applications and Success Stories

From offset printing to digital printing, screen printing, flexography, and gravure printing, each method offers unique benefits and applications. Businesses and individuals can leverage these techniques to create high-quality printed materials that meet their specific needs. Real-world examples and case studies demonstrate how different printing techniques have been successfully utilized in various industries to achieve marketing goals and produce visually appealing materials. By understanding the strengths and limitations of each printing method, readers can make informed decisions on selecting the right technique for their projects.